Minimizing construction noise

To help reduce noise, Skanska will:

- Install noise monitors throughout the construction area that can provide data to Skanska and WSDOT about noise levels.

- Install noise-screening fencing around parts of the construction area.

- Prohibit pure-tone backup alarms (the loud “beep, beep, beep” that trucks often make when driving in reverse).

- Require an on-site independent noise inspector during nighttime to ensure noise levels do not exceed what is allowed by the city of Seattle. These independent noise inspectors will have the authority to stop work if noise levels exceed permit limits.

Noise monitoring

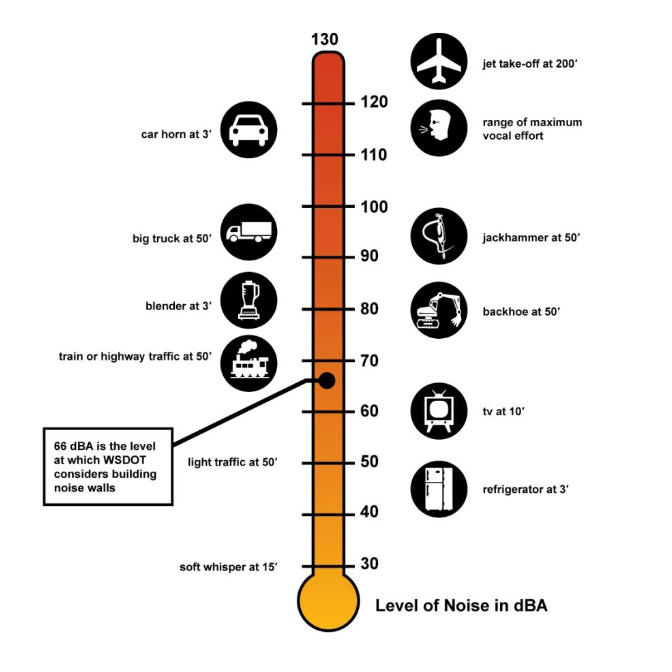

During daytime construction, noise should stay at an average of 85 decibels. This is about the same volume as standing 50 feet away from a moving freight train or operating a blender in your home.

Noise Mitigation Pilot Program

Did you know that WSDOT has a Noise Mitigation Pilot Program? The pilot program offers eligible households up to $3,500 towards noise mitigation, such as white noise machines, high-grade ear plugs, window inserts, window replacements and more. To see if you are eligible, please email us at sr520bridge@wsdot.wa.gov.

At night, noisy work like bridge and concrete demolition or pile installation will require a Temporary Noise Variance (TNV) from the city of Seattle. We will let nearby neighbors know about any work that needs a TNV 72-hours in advance.

Hotel accommodations during noisy work

When nighttime work is expected to be especially noisy and a TNV is required, we will notify nearby neighbors in advance and offer hotel accommodations. We will provide both standard and pet-friendly hotel options.

Typical work hours

Daytime work hours (as determined by the city of Seattle)

- Weekdays: 7 a.m. – 10 p.m.

- Weekends: 9 a.m. – 10 p.m.

- Most construction activities will occur during the day.

Nighttime work hours

- Weekdays: 10 p.m. – 7 a.m.

- Weekends: 10 p.m. – 9 a.m.

Vibration

Vibration will happen throughout the whole project. We want you to be ready for this when construction starts. Please watch the pile driving and vibration piling videos below to see how Skanska is working to reduce vibrations in your neighborhood.

Installing piles in Portage Bay

Pile installation involves driving a long metal tube (pile) into the ground or a lakebed to provide the foundation for a structure. Typically, piles are pushed and pounded into the ground using impact equipment – similar to a large, motorized hammer – that strikes the top of the pile until it is installed. The video below shows an example of pile driving at Colman Dock.

In the video above, crews working for WSDOT’s Colman Dock Project are seen piledriving with a “bubble curtain” to weaken the intensity of the underwater sound waves generated by the loud hammering. Skanska will use similar curtains to reduce impacts during in-water construction.

Pile driving will feel like rhythmic vibrations near the work zone. Neighbors may hear intermittent “thudding” noises when the impact hammers strike.

To reduce the impacts from pile driving, Skanska will primarily use a vibratory device that shakes the pile into the ground. The video below shows the difference in impacts when using a vibratory method instead of an impact method.

In the video above, crews working for WSDOT’s Colman Dock Project use a vibratory hammer to move the pile into the ground. After a certain depth, the soil may be too hard to vibrate a pile into and may require switching to impact hammering.

In some cases, vibratory hammers can produce enough vibration for you to feel or see in your home if you are located near the work zone. For example, the vibration levels can rattle dishes or make guitar strings hum but are not high enough to knock pictures off the wall. After a pile has been vibrated to a certain depth, Skanska may use an impact hammer during the day (which makes the loud “bang-bang” noise) to ensure the pile is lodged securely. Neighbors should expect a mix of both impact hammering and vibration hammering during construction.

Vibration-producing equipment

Pile installation isn’t the only type of work that may cause vibration. Neighbors can expect to experience vibrations when we demolish and rebuild the 10th Avenue East and Delmar Drive East overpasses, build the new Roanoke Lid and complete work on local streets. Some of the equipment you may see include:

- Hydraulic breakers and concrete pulverizers used for concrete panel and selected retaining walls.

- Excavators used for digging and trenching.

- Vibratory rollers used for paving.

- Concrete trucks and other trucks delivering heavy materials.

In the unlikely event construction has damaged a property, we have created a vibration damage fund for damages up to $50,000. If you believe your property has experienced damage as a result of vibration from construction, please send us email at sr520bridge@wsdot.wa.gov.

Utility work in your neighborhood

Before we start construction on a new project, we work with multiple utility companies to incorporate their infrastructure into the project. This ensures neighbors don’t experience major service disruptions.

For this project, we have several utilities that will need to be relocated. These include:

- Burying an above-ground power line that runs along East Roanoke Street in cooperation with Seattle City Light.

- Relocating a 42-inch waterline that runs under SR 520 so that it can be accessed for maintenance and repair when construction is complete.

- Realigning Lumen (fiber communications) utilities so their crews can access the lines once construction is complete.

What to expect during utility work

- Noise, dust and vibration when crews dig trenches for each of the utilities.

- Each utility company will notify customers of any planned shutoffs.

- Lane closures around the work zones near Boyer Avenue East, East Roanoke Street, 11th Avenue East, Delmar Drive East and Federal Avenue East.

- Seattle City Light will begin their electrical utility upgrades in fall 2024 and continue into early 2025.

- We are still determining the final location for the relocated 42” water pipe. More details on this work will be shared later.

Environmental considerations

During construction, we use environmentally friendly practices to lower our ecological footprint. We also work with communities to mitigate the environmental effects of our construction program, in part by making significant improvements to local parks and sensitive natural areas.

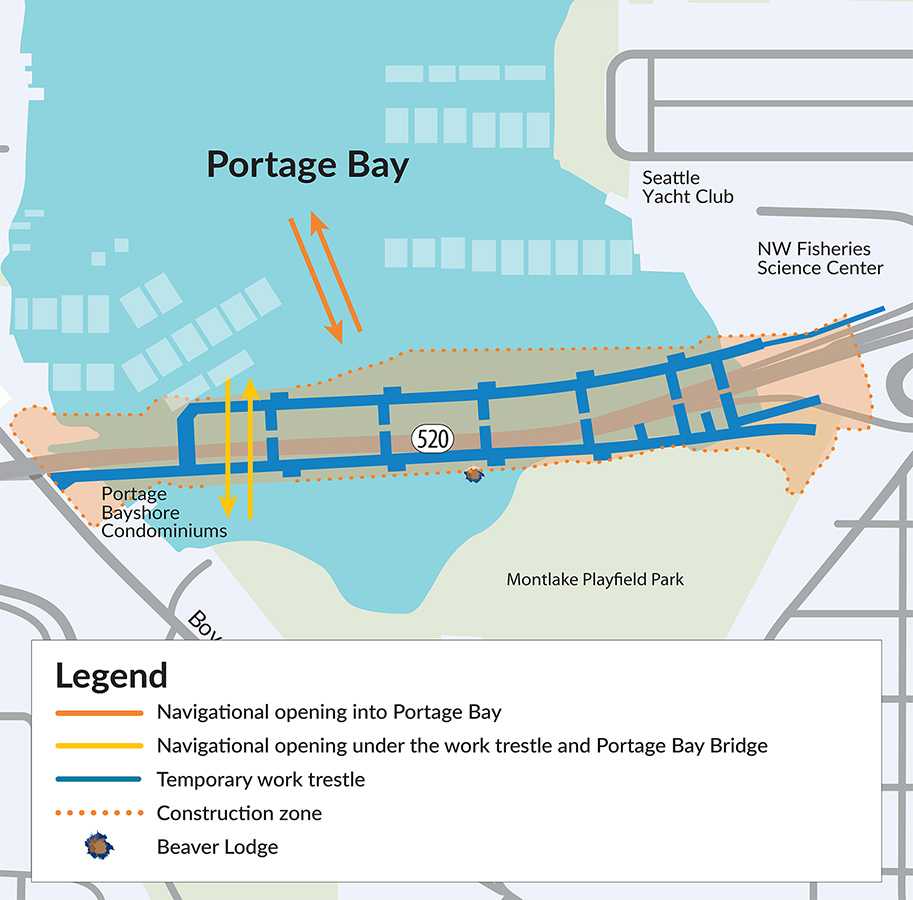

Working in Portage Bay

We know that there are a lot of factors we need to consider when completing construction in Portage Bay. From water quality to supporting aquatic life, we have worked with the contractor and local state agencies to ensure we are minimizing impacts whenever we can. To reduce impacts, Skanska will:

- Maintain recreational boater access in and around the work zone by using clearly marked boundaries.

- Monitor turbidity – the levels of particles in water – so crews can adjust construction methods and plans as needed.

- Turbidity may appear as cloudy or hazy water caused by sediment that has been disrupted during construction.

- To reduce turbidity, crews may use underwater containment systems, spill kits and other best management tools help water stay clean and clear.

- Use reinforced hydraulic hoses and floating oil containment devices (oil booms) to reduce the risk of leaks in Portage Bay.

- Use “curtains” underwater to reduce noise and vibration.

- Check out the video in the Vibration section to see an underwater curtain in action!

Beaver Lodge in Portage Bay

Additionally, we know that the existing beaver lodge in Portage Bay near the Montlake Playfield Park is important to the community. After some additional consideration, our partners have determined that the best way to limit impacts to the beaver lodge is to keep it in place. Relocating the beaver lodge puts the beavers at risk of having unintended negative health consequences or even death.

Working in your community

Skanska is committed to reducing environmental impacts in your community by:

- Reducing debris in the neighborhood by having a dedicated street sweeper clean local streets.

- Reducing dust by paving all entrances and exits to staging sites. Car and boat wash vouchers are available for neighbors who have experienced increased dust.

- Providing an on-site stormwater treatment system to manage stormwater during construction.

- Installing noise-screening fencing around the Roanoke Lid construction site, the WSDOT Peninsula and the Fuhrman Avenue East staging site to reduce environmental noise.

Skanska has also developed a Community Construction Management Plan with WSDOT. Continue to the Community Construction Management Plan page to learn more.